Your Playbook for Procuring Injection Molding Services from China

The important meeting has recently finished, your new product has been approved, the schedule is tight, and the budget is, let’s say, constrained.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Of course, you acknowledge. It seems sensible at first glance. Savings can be substantial. But your mind is already racing. You’ve heard all the horror stories, right? Quality failures, endless communication gaps, shipments arriving months late and nothing like the prototype. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

Here’s the thing, though. Sourcing plastic mold company can be a calculated project. It’s a project, just like any other. And like any project, it succeeds or fails based on the process you follow. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Disregard those scary tales. Here’s a practical playbook to nail it.

First Things First: Your Homework

Before you mention “supplier” or browse Alibaba, organize your internal data. In fact, most overseas manufacturing headaches stem from a vague or incomplete RFQ. You cannot expect overseas partners to interpret your unspoken requirements. Sending a vague request is like asking a builder to quote you for “a house.” You’ll get wildly varied quotes that are useless.

Your goal is to create a Request for Quotation, or RFQ, package that is so clear, so detailed, that it’s nearly impossible to misinterpret. This becomes the bedrock of your sourcing project.

So, what goes in it?

Start with your 3D design files. These are non-negotiable. Provide files in common formats (e.g., STEP, IGS) to prevent import issues. This serves as the definitive part geometry reference.

However, 3D alone won’t cut it. Include precise 2D engineering drawings. Here you specify what 3D can’t show. I’m talking about critical tolerances (like ‘25.00±0.05 mm’), material specifications, required surface finishes, and notes on which features are absolutely critical to function. If a specific surface needs to be perfectly smooth for a seal, or a particular hole diameter is vital for an assembly, your 2D drawing needs to shout it from the rooftops.

After that, material choice. Don’t label it simply “Plastic.” Even “ABS” alone is too vague. Get precise. Specify SABIC Cycolac MG38 in black, if that’s the resin you need. Why be exact? Because resin grades number in the thousands. Specifying the exact resin grade ensures you get the strength, flexibility, UV resistance, and color consistency you planned for with plastic mold injection.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Finally, include the business details. What’s your forecasted annual volume (EAU)? You must specify if it’s a 1K-part tool or a 1M-part production run. Cavity count, tooling cost, and per-unit pricing depend on volume.

Finding the Right Supplier

Now that your RFQ is pristine. now, who do you send it to? The internet has made the world smaller, but it’s also made it a lot noisier. Locating vendors is easy; vetting them is the real challenge.

You’ll probably kick off on Alibaba or Made-in-China. These are great for casting a wide net and getting a feel for the landscape. Use them to build a shortlist, not the final list. Aim for a preliminary list of 10–15 potential partners.

But don’t stop there. Think about engaging a sourcing agent. They do cost extra. But a good one has a vetted network of factories they trust. They are your person on the ground, navigating the language and cultural barriers. On your first run, this is like insurance. Think of it as insurance for your project timeline.

Another classic method? Trade shows. If you can attend, shows such as Chinaplas transform sourcing. Meeting onsite is unbeatable. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Also, leverage the tried-and-true referral network. Tap your professional contacts. Peer endorsements carry huge weight.

Sorting the Contenders from the Pretenders

Now you have your long list of potential suppliers and you’ve sent out your beautiful RFQ package. the quotes will start trickling in. Some prices will undercut logic, others will shock you. Now, sift through and shortlist 2–3 reliable candidates.

What’s the method? It involves both metrics and gut feel.

First, look at their communication. Are their replies prompt and clear? Do they communicate effectively in English? But the key: do they probe your RFQ? Top vendors will critique and inquire. “Have you considered adding a draft angle here to improve ejection?” or “We see your tolerance requirement here; our CMM can verify that, but it will add to the inspection time. Is that acceptable?” Consider that a big green light. It proves their expertise and involvement. A “Sure, no issues” vendor often means trouble.

Afterward, verify their technical arsenal. Request their machine list. Review examples of parts akin to your design. A small-gear shop won’t cut it for a big housing.

Then comes the audit. You can’t skip this. You would never hire a critical employee without an interview, so why would you send tens of thousands of dollars for a tool to a company you’ve never truly vetted? You can travel or outsource a local inspector. They’ll send a local inspector to the factory for a day. They will verify the company is real, check their quality certifications like ISO 9001, assess the condition of their machinery, and get a general feel for the operation. That small investment can save you thousands.

Transforming CAD into Real Parts

Once you’ve chosen your supplier. you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the process kicks off.

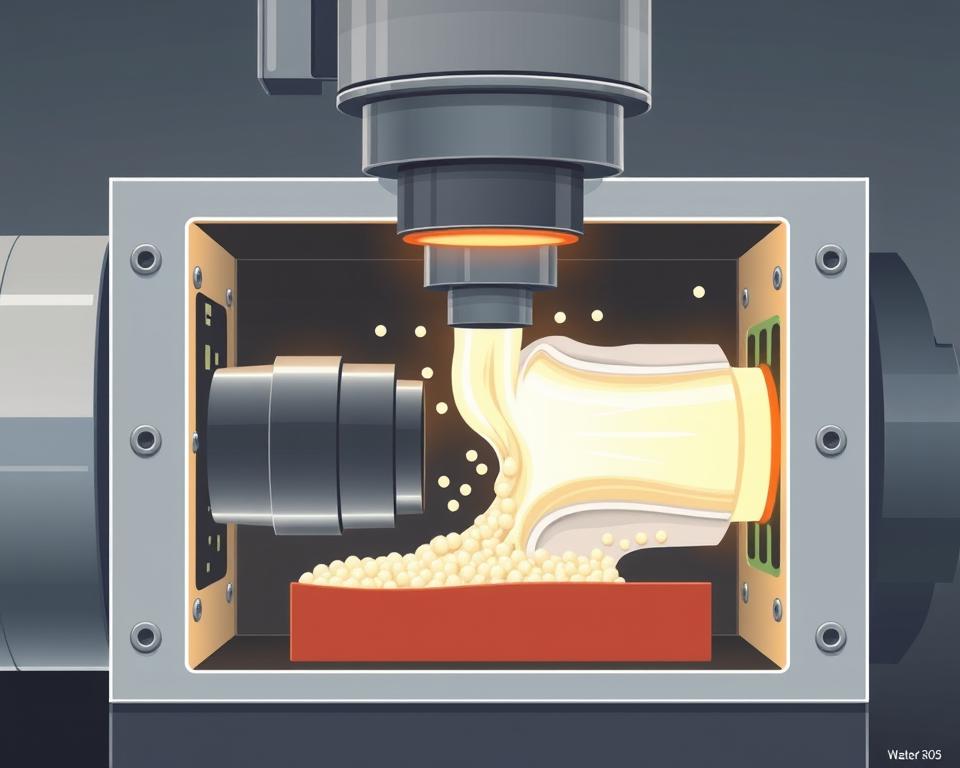

Initially, expect a DFM report. Design for Manufacturability (DFM) is essential. This is your supplier’s formal feedback on your part design. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a two-way partnership. You work with their engineers to refine the design for optimal production.

Once the DFM is approved, they’ll start cutting steel to make your injection mold tool. Weeks on, you receive the thrilling “T1 samples shipped” notification. These are the very first parts off the new tool. It’s your test of success.

Expect T1s to need tweaks. This is normal! There will be tiny imperfections, a dimension that’s slightly out of spec, or a blemish on the surface. You critique, they refine, and T2 plastic mold in China parts arrive. It could require several iterations. Plan for this loop in your schedule.

Eventually, you will receive a part that is perfect. It matches all specs, has a pristine finish, and works as required. This is your golden sample. You ratify it, and it becomes the quality yardstick for production.

Final Steps to Mass Production

Landing the golden sample is huge, yet the project continues. Now you’re entering the mass production phase. How can you keep part #10,000 matching your golden sample?

Put a strong QC process in place. This often involves a pre-shipment inspection. Bring in an external QC firm. They’ll sample parts, check dimensions and finish versus your drawings and golden sample, and report. They’ll send you a detailed report with photos and measurements. After your approval, you release the shipment and final funds. This step saves you from a container of rejects.

Lastly, plan logistics. Know your shipping terms. Are you on FOB terms, where they load and you take over? Or EXW, where you handle everything from their gate? These details have a big impact on your final landed cost.

Sourcing from China is a marathon, not a sprint. It hinges on strong supplier relations. See them as collaborators, not vendors. Open dialogue, trust, and rigorous procedure deliver results. Certainly, it’s complex. However, armed with this guide, you’ll secure savings and keep high standards intact. You’ve got this.